Tool up and get DIY projects done better and faster than ever. See how a pro—a good one, not Joey-Bag-A-Donuts—approaches projects. And, DIYer or pro, check out some cool tool tips that’ll keep you working faster and safer than ever.

Are your tools talking to you? What are they saying? A Concord Carpenter and tool expert Rob Robillard joins us to talk about the secret—and not so secret—messages our tools send us while we work.

It’s stuff the pros know that makes their projects look so easy. Why is smoke pouring out of my saw? Is it the saw? Rob points out that a blade, even on an expensive miter saw, isn’t supposed to last ten years.

And—please nooooooo—a chisel is *NOT* designed to open a paint can and still remain a functioning chisel after that trauma. It’s a precision instrument, not a lever. But a painter’s multi tool is. THAT’s what you open paint cans with.

From hammer snobs to tool snobs Rob breaks it down. And even though he is frustrated with how sledge hammers are used on DIY TV shows, he shares some ways that they are used for smart DIY. Yes, your tools are talking to you.

Rob Robillard, ace remodeling contractor and creator of A Concord Carpenter, Hangs Out with us to talk DIY projects that work. And little signals your tools might be sending you that things may not be headed in the right direction. And for you seasoned pros, Rob’s tips for efficient cutting, measuring and job-getting-done-ing will have you wanting to work on his job sites and read his tool reviews.

Be sure to check out this hangout with Rob Robillard. We want to hear your thoughts! So share your comments and questions on Google+, YouTube or myfixituplife@myfixituplife.com.

Click here to see more from the Concord Carpenter, Rob Robillard.

Watch this video on YouTube

If you’ve never watched Google+ hangouts, here’s what you need to know to check it out.

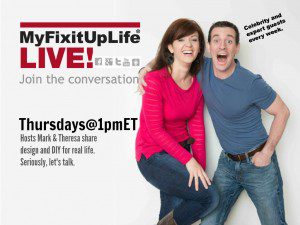

MyFixitUpLife hosts Mark and Theresa are hosting LIVE Google+ Hangouts every weekday at 1pmET.

You’ll be able to ask your questions and make comments on G+, Twitter, FB, and/or YouTube during every interview. And we’ll be ready to share the answers live on MyFixitUpLife LIVE!

So here’s the lowdown on Google+ Hangouts:

What is a G+ hangout?

It’s a live video chat hosted publicly by MyFixitUpLife on the MyFixitUpLife talk Google+ account. You don’t need a Google+ account to watch.

How can I watch?

You can watch on the Google+ Hangout event page on MyFixitUpLife.com or Google+. If you have a G+ account, you can RSVP and let your friends know you’re going. You can also email, tweet, Facebook, or even face-to-face invite friends to watch.

Do I need a G+ account?

You do not have to have an account to watch the hangout. You can watch on YouTube, on Google+ or on MyFixitUpLife.com.

What if I miss the hangout?

You can watch every Google+ Hangout later on our MyFixitUpLife YouTube channel.

[…] tile, or cutting out studs and plates from a horribly remuddled partition wall addition, the phrase “right tool for the job” exists because it’s true. The reason the saw at hand is the most important isn’t because it’s […]

I am definitely going to plow through with best efforts with this somewhere and learn lessons before using it somewhere where its a bigger deal to have to redo. Thinking of drying.. soaking in preservative/staining and then a couple coats of Helmsman/Urethane. Thanks for the thickness measure. Worried about the bark breaking away, but we’ll see. Ive got a lot of areas where I need to control grass/weeds and or transition areas. Plus grand schemes of pockets of outdoor living areas.. all of which I would like to keep concrete type flooring to a minimum. Anyway.. very cool. Thanks-Todd

Todd–Thanks for checking in and thank you. We did not make that project, but we feel the same way you do. Yes, I’m certain it’s either sanded grout or mortar between the logs. And it looks like it has a sealer on it, which is the tint you see.

If you’re thinking about this project, there are a few things I know I’d consider. Either use seasoned wood or expect to re-grout when green material shrinks. I wouldn’t cut the discs less than 1 1/2-2-inches thick. And I’d make sure to have a vapor barrier of some sort between them and the subfloor. At the minimum I’d seal the bottom ends of the logs with a few coats of urethane.

As for sanding–lots of options there. Are you considering doing this project?

Hello,

Firstly… great site… really interesting stuff nearly everyday… tough to do.

Where can I find the details on that floor made of log “tiles” (cross sections) and what looks like mortar or something in between them? Probably not an easy project, but wow what a cool floor option for (at minimum) outdoor transition areas or inside a guest cabin or foyer or something. THanks in advance. Todd