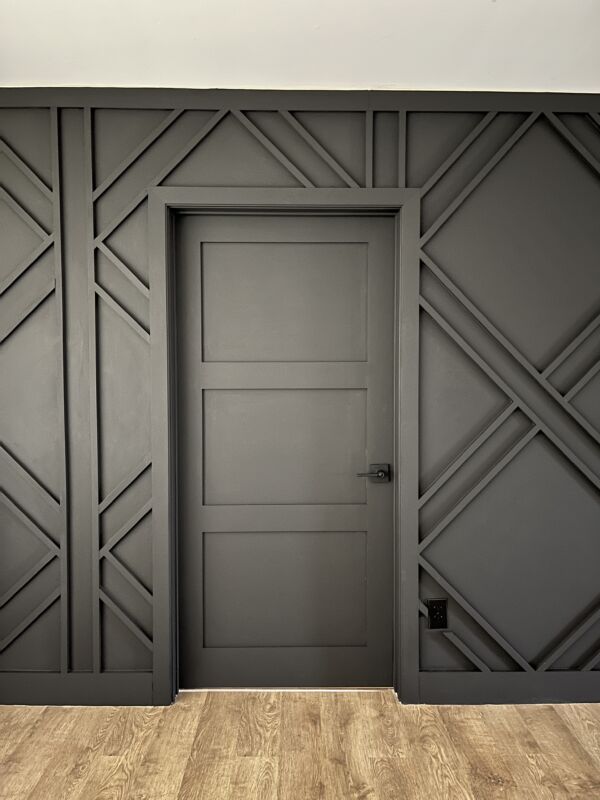

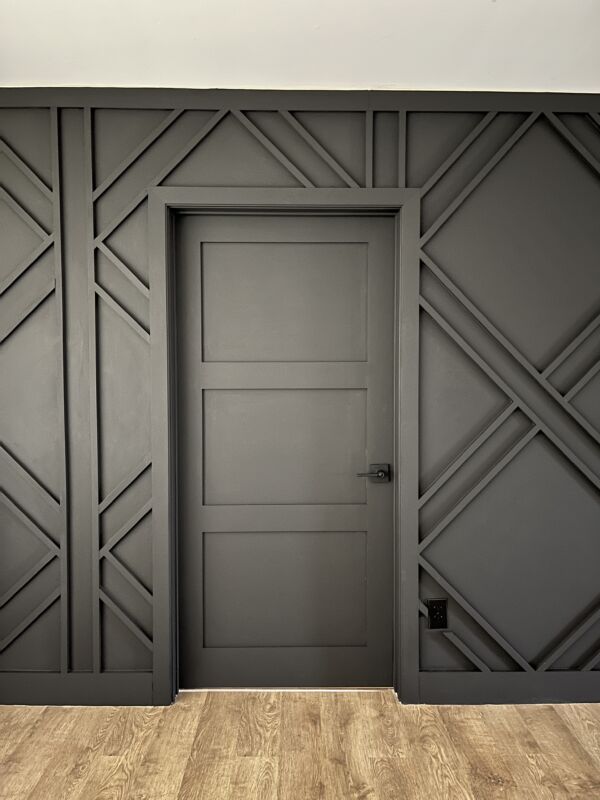

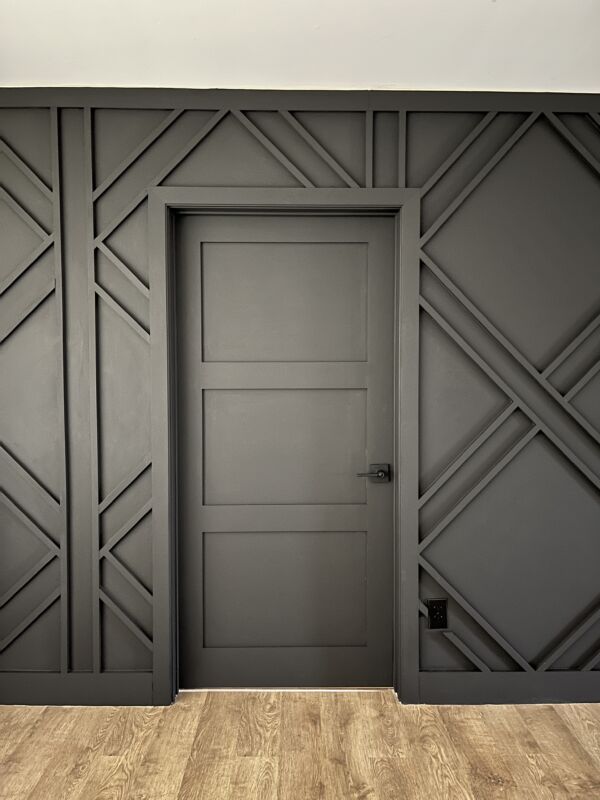

We transformed a lifeless and forgettable dining room wall into a stunning sexy-modern geometric feature wall in matte black with a wood alternative made from rice husks called Acre by Modern Mill.

In this video we build a feature wall–aka, accent wall.

Whenever we approach a home improvement project for a client, we go through the regular steps of evaluating the space, discussing vision, reviewing inspiration images, reviewing budget and timeline, and explaining the entire process from set-up through clean-up, so the homeowner knows what to expect and we know what to deliver to meet their needs.

In the video, you’ll also see the how-to steps for creating the feature wall and many details that are important to creating a well-crafted geometric wall that will last and become a showstopper for friends and family when they visit.

Here are some of the video key moments:

- Tips for removing and hanging a door

- Integrating a door with a feature wall

- Removing door casing and baseboard

- Color and coating selection

- Tools. A brad nailer is your friend on a feature wall.

- Coating–aka, paint–application

- Using Acre by Modern-Mill composite 1-by instead of wood

- Spray painting the cold air return grill and swapping out device covers

Layout is essential for making a geometric pattern fit inside a wall space, especially if the goal is to create symmetry.

After all of the Acre by Modern Mill pieces were cut and installed, we filled all of the nail holes and prepped for paint.

Stuff We Left Out

Theresa and I were at borderline DefCon 5 trying to understand each other during layout. I kept thinking I was understanding what she was saying. I kept being wrong. She could see it in her head. I need to see things in real life, so I made a jig that enabled us to mark the centers of the double Xs and keep them evenly spaced

The double strut design here is difficult to wrap your head around. The goal is to make each panel–each double X–the same as each other

More On Materials

We used Acre for a constellation of reasons, among them: Uber stability and ease of milling. Acre is also versatile, so we used it as various forms of trim. You’d be surprised what you can whip up with a table saw and a router with a cove bit

Because we milled each piece of accent wall trim on the table saw from 1×12 stock, we had saw marks to sand out. While Acre is more expensive than finger joint primed pine, its ease of sanding alone made it worth the price point. Add to that it takes paint wonderfully and it can be fastened with nails, staples or screws. We also like that, unlike some finger joint primed pine, Acre is made in the US of A and from over 50% upcycled rice husks. It works like wood

Feature walls are extravagant-ish. We used a Sherwin Williams exterior paint I’ve used on doors before that is technically “flat” but also has a slight film that makes it easy to clean to deliver a matte finish. It’s an acrylic that has an ultradeep base. We choose Emerald and the color: Sherwin-Williams Tri-Corn Black

Details and How-To Tips

If you’re making your own feature wall, here are some tools and ideas to consider.

Be ruthless with layout. Check, double check and double check again a different way that whatever design you have is going to radiate out from whatever control points you have selected. In the feature walls we’ve made–and they are fun–everything kind of emanates from a single source, whether that’s a single board or a point in space

No wall is perfectly flat. There may be some shimming or sanding required when all is said and done. Some voids don’t require an actual shim. Here’s a nailing trick to get piece flush without shims.

A brad nailer is our go to for this kind of installation. Finish nailers work, but the nail is pretty big

Plan on three coats of paint for bold colors. If you are cutting different colors into each other, use high quality paint brushes.

Details around the door, integrating hardware and switch plates is also part of delivering a seamless design.

Note: This project was created in collaboration with Modern Mill, and we were compensated for using the Acre. However, we choose Acre for many other client projects because we feel it’s the best material for many home improvement projects.

About the Author